Woodworking Router Bits: Your Essential Guide to Choosing the Right Tools

*We may earn a commission for purchases made using our links. Please see our disclosure to learn more.

Having a strong passion for woodworking, I understand the significance of using the right tools for each project. When it comes to woodworking routers, one crucial component that often determines the quality of your work is the router bit. With a wide array of options available, selecting the appropriate router bit for the job can greatly enhance your woodworking experience. In this article, I’ll walk you through everything you need to know about woodworking router bits and provide helpful suggestions to guide your choices.

Woodworking router bits are specialized cutting tools designed to shape, trim, and hollow out wood. They attach to a router machine and allow woodworkers to create intricate profiles, joinery, and decorative edges. Whether you’re a seasoned professional or a beginner in the craft, understanding the different types of router bits and their applications is essential for achieving precise and professional results.

Understanding Woodworking Router Bits

To choose the right router bits for your woodworking projects, let’s start by gaining a basic understanding of their structure and function. Router bits consist of a shank, a body, and a cutting edge. The shank is the cylindrical part that attaches to the router machine, while the body holds the cutting edge, determining the profile or shape it creates.

Types of Router Bits

Router bits come in various types, each serving a specific purpose. Some common types include:

- Straight Router Bits: These bits have a uniform cutting diameter and are ideal for creating straight cuts, grooves, and dadoes.

- Flush Trim Router Bits: Designed for trimming the edge of one material to match the contour of another, flush trim bits ensure precise and seamless flush cuts.

- Cove Router Bits: Cove bits create concave profiles, often used for decorative purposes or creating smooth edges on furniture.

- Chamfer Router Bits: Chamfer bits produce beveled edges or angles, adding a professional touch to your woodwork and providing a finished look to tabletops, cabinets, and more.

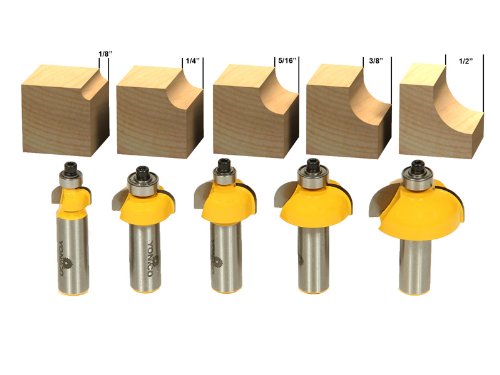

- Roundover Router Bits: Roundover bits are perfect for softening edges and creating a smooth, rounded profile. They are commonly used on furniture, shelves, and moldings.

- Rabbeting Router Bits: Rabbeting bits cut a groove along the edge of the wood, allowing for the insertion of another piece or creating a recessed area.

- Beading Router Bits: Beading bits create decorative rounded edges with a small bead detail. They add elegance and sophistication to woodworking projects such as picture frames or jewelry boxes.

- V-groove Router Bits: V-groove bits carve out a V-shaped channel, often used for decorative purposes or creating crisp lines in signs and lettering.

Understanding the different router bit profiles empowers you to choose the right tool for the specific task at hand, ensuring clean, precise cuts and achieving the desired aesthetic results.

Key Features to Consider when Choosing Router Bits

In addition to the various profiles, there are other important factors to keep in mind when selecting router bits:

- Bit Material: Router bits can be made from high-speed steel (HSS), carbide, or solid carbide. Carbide bits are generally more durable and capable of withstanding high heat and heavy use.

- Coating: Some router bits come with coatings that enhance their performance and longevity. Common coatings include titanium nitride (TiN) and titanium aluminum nitride (TiAlN), which provide improved wear resistance and reduce friction.

By considering these key features, you can ensure that your router bits are suitable for the specific woodworking tasks you undertake.

Choosing the Right Router Bit for the Job

Now that we have a good understanding of router bits and their profiles, it’s time to delve into the process of choosing the right bit for your woodworking project. Here are some important considerations to guide you:

Determining the Type of Cut Needed

First, identify the type of cut you want to achieve. Do you require a straight cut, a beveled edge, or a decorative profile? Understanding the desired outcome will help you narrow down your options.

Selecting the Appropriate Router Bit Profile

Based on the desired cut, select the router bit profile that best matches your requirements. Consider the shape, size, and depth of the cut you want to create.

Considering the Bit Material and Coating

Take into account the material you’ll be working with and the duration of the project. If you’re working with hardwoods or planning an extended woodworking session, carbide bits with coatings will provide increased durability and longevity.

Choosing the right router bit for the job is crucial to achieving clean and precise cuts. Investing time in the selection process will ultimately save you from frustration and ensure the success of your woodworking endeavors.

Popular Router Bit Profiles and Their Uses

To further assist you in your woodworking journey, let’s explore some popular router bit profiles and the tasks they excel at:

Straight Router Bits

Straight router bits are versatile and essential for making grooves, dados, and simple edge cuts. They are the go-to choice for creating clean and straight lines in your woodworking projects.

Flush Trim Router Bits

Flush trim bits are invaluable when you need to trim one material to match the contour of another. They ensure seamless and precise flush cuts, making them ideal for edge banding, laminate trimming, and template routing.

Cove Router Bits

Cove bits are perfect for adding decorative edges and creating concave profiles. They can be used to shape table legs, chair arms, and moldings, adding elegance and sophistication to your woodwork.

Chamfer Router Bits

Chamfer bits are excellent for creating beveled edges or angles to your woodworking projects. They can be used to create decorative edges, remove sharp corners, and add visual interest to tabletops, cabinets, and other furniture pieces.

Roundover Router Bits

Roundover bits are ideal for softening edges and creating a smooth, rounded profile. They are commonly used to give a finished look to shelves, tabletops, and moldings. Roundovers also prevent sharp edges, making them safer and more comfortable to touch.

Rabbeting Router Bits

Rabbeting bits are designed to cut a groove along the edge of the wood, allowing for the insertion of another piece or creating a recessed area. They are often used in joinery, box-making, and creating panels.

Beading Router Bits

Beading bits are excellent for adding decorative rounded edges with a small bead detail. They bring a touch of elegance and craftsmanship to woodworking projects such as picture frames, jewelry boxes, and trim work.

V-groove Router Bits

V-groove bits create V-shaped channels, which can be used for decorative purposes or creating crisp lines in signs, lettering, and decorative panels. They are versatile tools that add depth and visual interest to your woodworking creations.

By familiarizing yourself with these popular router bit profiles and their uses, you can make informed choices that align with your woodworking goals and achieve outstanding results in your projects.

Maintaining and Caring for Router Bits

To ensure the longevity and performance of your router bits, it’s essential to follow proper maintenance and care practices. Here are some tips to keep your router bits in top shape:

Cleaning and Removing Built-Up Resin

Resin buildup can occur on router bits during use, affecting their cutting performance. Regularly clean your bits using specialized router bit cleaning solutions or warm soapy water. Use a brush to remove any debris or resin that has accumulated on the cutting edges.

Sharpening Router Bits

Over time, router bits may become dull, leading to less efficient cutting and potentially damaging the wood. Invest in a high-quality sharpening kit or consider professional sharpening services to maintain the sharpness of your bits. Remember to follow the manufacturer’s instructions and take necessary safety precautions when sharpening router bits.

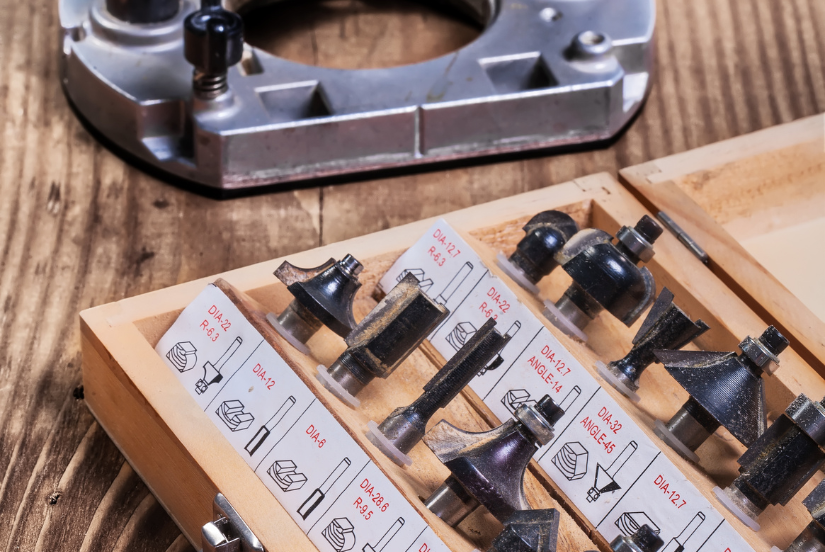

Proper Storage to Prevent Damage

When not in use, store your router bits in a dedicated case or organizer. This helps prevent damage to the cutting edges and reduces the risk of accidents when handling the bits. Avoid tossing them into a toolbox where they can collide with other tools or become dull due to improper storage.

By implementing these maintenance practices, you’ll maximize the lifespan of your router bits and ensure consistent, high-quality cuts in your woodworking projects.

Safety Precautions and Best Practices

Safety should always be a top priority when working with woodworking router bits. Follow these essential precautions and best practices to protect yourself and achieve optimal results:

Using Protective Equipment

Always wear safety goggles or a face shield to protect your eyes from flying debris. Additionally, use hearing protection and a dust mask to safeguard your ears and respiratory system from wood particles and noise.

Securing the Workpiece

Ensure that the workpiece is firmly secured using clamps or a vise before operating the router. This prevents the wood from shifting or vibrating during the cutting process, reducing the risk of accidents and ensuring accurate cuts.

Maintaining a Steady Feed Rate

Keep a consistent and steady feed rate when moving the router along the workpiece. This helps prevent burning the wood or causing tearout. Avoid rushing or applying excessive force, as it can result in less precise cuts and potential damage to the router bit.

Avoiding Excessive Force

Let the router bit do the cutting work for you. Applying excessive force can strain the router motor and lead to poor results. Instead, use a gentle and controlled approach, allowing the bit to cut through the wood smoothly and effortlessly.

Troubleshooting Common Router Bit Issues

Even with careful planning and execution, you may encounter some common issues while using router bits. Here are solutions to troubleshoot and overcome these challenges:

Burning or Scorching of Wood

If you notice burning or scorching of the wood during routing, it indicates excessive heat generated by the bit. To prevent this, reduce the router speed or adjust the feed rate. Using a bit with a higher number of flutes can also help dissipate heat more effectively.

Tearout and Splintering

Tearout and splintering can occur when the router bit exits the wood, leaving an uneven or ragged edge. To minimize tearout, ensure that the workpiece is properly supported, and consider using a backing board to provide additional support. Using a router bit with a down-shear design or a spiral flute can also help reduce tearout.

Chattering or Vibration

Chattering or vibration can result in uneven cuts and a poor finish. To address this issue, check that the router bit is securely tightened in the collet. Additionally, ensure that the router’s speed is appropriate for the bit and adjust the feed rate to achieve a smooth and steady motion.

By applying these troubleshooting techniques, you can overcome common challenges and achieve the desired precision and quality in your woodworking projects.

Final thoughts

Selecting the right woodworking router bits is crucial for achieving exceptional results in your projects. By understanding the various types of router bits, their profiles, and their applications, you can make informed decisions that align with your woodworking goals. Additionally, proper maintenance, adherence to safety precautions, and troubleshooting techniques will ensure the longevity of your router bits and enhance your woodworking experience.

Investing time and effort in selecting the right router bits, mastering their use, and caring for them properly will undoubtedly elevate your woodworking craftsmanship and allow you to create beautiful, professional-grade pieces.

FAQs (Frequently Asked Questions)

1. Can I use a router bit designed for wood on other materials like metal or plastic?

It is not recommended to use router bits designed for wood on other materials. Different materials require specific cutting tools designed for their properties. Using a wood router bit on metal or plastic can lead to poor results, damaged bits, and potential safety hazards. Invest in router bits specifically designed for the materials you intend to work with.

2. How often should I replace my router bits?

The frequency of replacing router bits depends on several factors, such as usage, material hardness, and maintenance. As a general guideline, regularly inspect your bits for signs of wear, such as dullness or chipped edges. Replace them when they no longer perform optimally or exhibit signs of damage that cannot be repaired through sharpening.

3. What is the difference between a plunge router bit and a non-plunge router bit?

A plunge router bit is designed to create cuts starting from the surface of the wood, allowing you to plunge the bit into the material. This is ideal for creating cutouts, mortises, or stopped cuts. Non-plunge router bits, on the other hand, are primarily used for edge shaping and trimming, where the bit remains in constant contact with the wood throughout the cut.

4. Can I use a larger diameter router bit in a smaller router?

It is important to use router bits that are compatible with the capacity of your router. Using a larger diameter bit in a smaller router can strain the motor, leading to overheating and potential damage. Refer to your router’s manual or consult the manufacturer to determine the maximum bit diameter your router can accommodate.

5. Are carbide-tipped router bits worth the investment?

Yes, carbide-tipped router bits are definitely worth the investment. Carbide is a hard and durable material that can withstand the rigors of woodworking and maintain its sharpness for longer periods compared to other materials. Carbide bits are highly resistant to wear, heat, and abrasion, making them ideal for heavy-duty tasks and extended use. While carbide-tipped bits may have a higher initial cost, their longevity and superior cutting performance make them a valuable investment for any woodworking enthusiast or professional.

Remember, using high-quality router bits not only enhances the precision and quality of your woodworking projects but also ensures a safer and more enjoyable experience overall. So, consider investing in carbide-tipped router bits to reap the benefits of their durability and exceptional cutting capabilities.